Vacuum Brazing

Byron Products is a leading provider of vacuum brazing solutions.Our extensive history of joining materials across many industries has given us the expertise to offer assembly and preparation of intricate and tight-tolerance assemblies for brazing.Utilizing the most up-to-date and upgraded technology available, we consistently meet deadlines and deliver industry-grade products.

Vacuum Brazing at Byron Products

Our specialty vacuum brazing services are guaranteed to produce resilient and durable joints by leveraging different customizable variables with careful consideration. Through our broad scope of capabilities and processes, we can confidently achieve your project’s vacuum brazing requirements and specifications.

When you choose Byron Products for your vacuum brazing needs, your project will receive a custom process supported by daily customer service at a competitive price.

- Develop tooling and fixturing solutions in-house

- Provide direct customer service every step of the way

- Offer well-maintained furnaces and equipment

- Develop and write detailed process plans

- Fulfill testing requirements in-house

- Run furnaces with infinite control of parameters (vacuum pressure, temperature, ramp rates, hold time, gas type, etc.)

We believe communication is the key to developing successful and efficient solutions unique to each customer process. Regardless of the size or complexity, you can trust us to deliver optimal results that will ensure your success.

What is Vacuum Brazing?

Vacuum brazing is a method that combines two elements using a brazing material. Assemblies with applied braze alloy are placed inside a vacuum brazing furnace and heated above liquidous temperature.

The parts are held at temperature for a duration called out by the recipe and then cooled to a solidus state temperature, during which dissimilar materials can be joined. Parts are thoroughly handled and inspected for cleanliness/ contamination, both before and after furnace brazing. Our team of professionals carefully consider each unique order and furnace run to ensure qualified parts every time.

Benefits of Vacuum Brazing:

Vacuum brazing is used to meet assembly requirements and prerequisites when other joining methods are insufficient. Some of its benefits include:

- Robust and reproducible joints

- Flux-free joints

- Braze components with complex geometries

- Clean, strong, bright, & high-quality joints

- Cost effective process

- Multi-stage process capability

Applications of Vacuum Brazing

There are manufactured assemblies that require brazing in almost any industry you can think of. As a contract manufacturer, Byron Products proudly serves an array of industries to produce clean brazed parts with varying functions. Some common applications include:

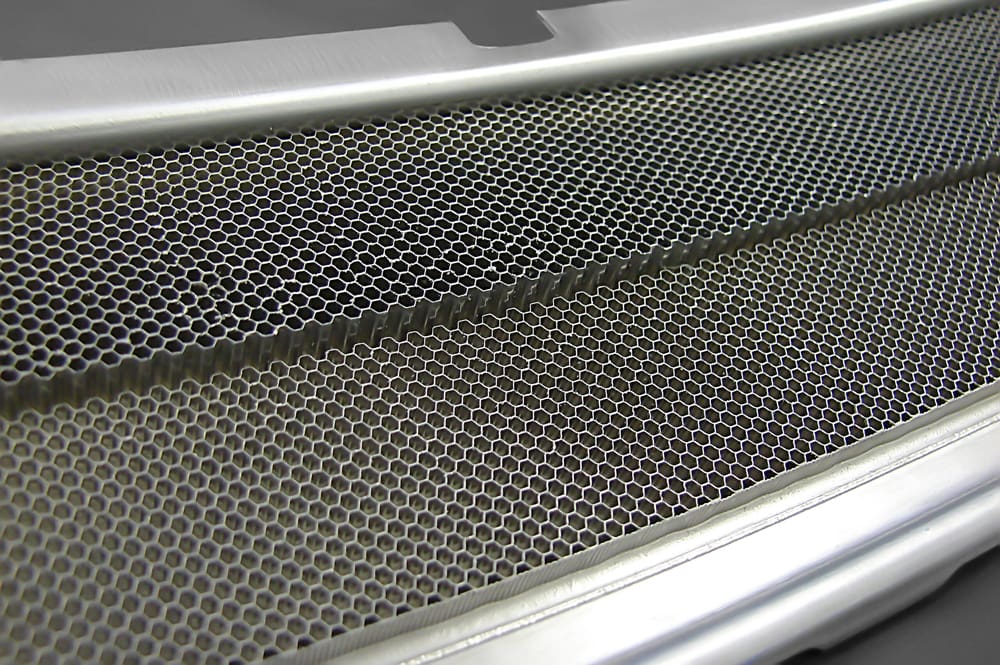

- Honeycomb Brazing

- Heat Exchangers

- Igniters

- Pressure Vessels

- Turbine Engine Components

- Hydraulic Fittings & Manifolds

Let Us Fulfill Your Vacuum Brazing Needs

We’re experts who specialize in vacuum brazing, so you can trust us to produce accurate and consistent results. With our help, you can experience success in all your projects. We have a wide range of operations available, and our team can provide sound advice if you need help determining what is best for your project.

Contact us today if you’re interested and want to know more about our vacuum brazing process. You may also request a quote, and we can develop a unique solution tailored to your needs!

Process / Capabilities

- Nickel Brazing

- Gold Brazing

- Copper Brazing

Advantages

- Large Batch Runs

- Small to Large Batches

- Clean Atmosphere

- Inclusion-free Braze Joint

- Controllable Furnace Run Parameters

- Uniform Temperature Control

- Cost Effective Process

Industries Served

- Aerospace

- Power Generation

- Medical

- Automotive

- Defense

- Commercial

Secondary Operations

- Assembly

- Cleaning

- Machining

- Grinding/Benching

- Blasting

- Non Destructive Testing

Certifications

- NADCAP approved

- AS9100 D/ISO 9001:2015

- AS9100C

- GE Approved

- Rolls-Royce Approved

- Honeywell Approved

- Siemens Approved