Honeycomb Brazing

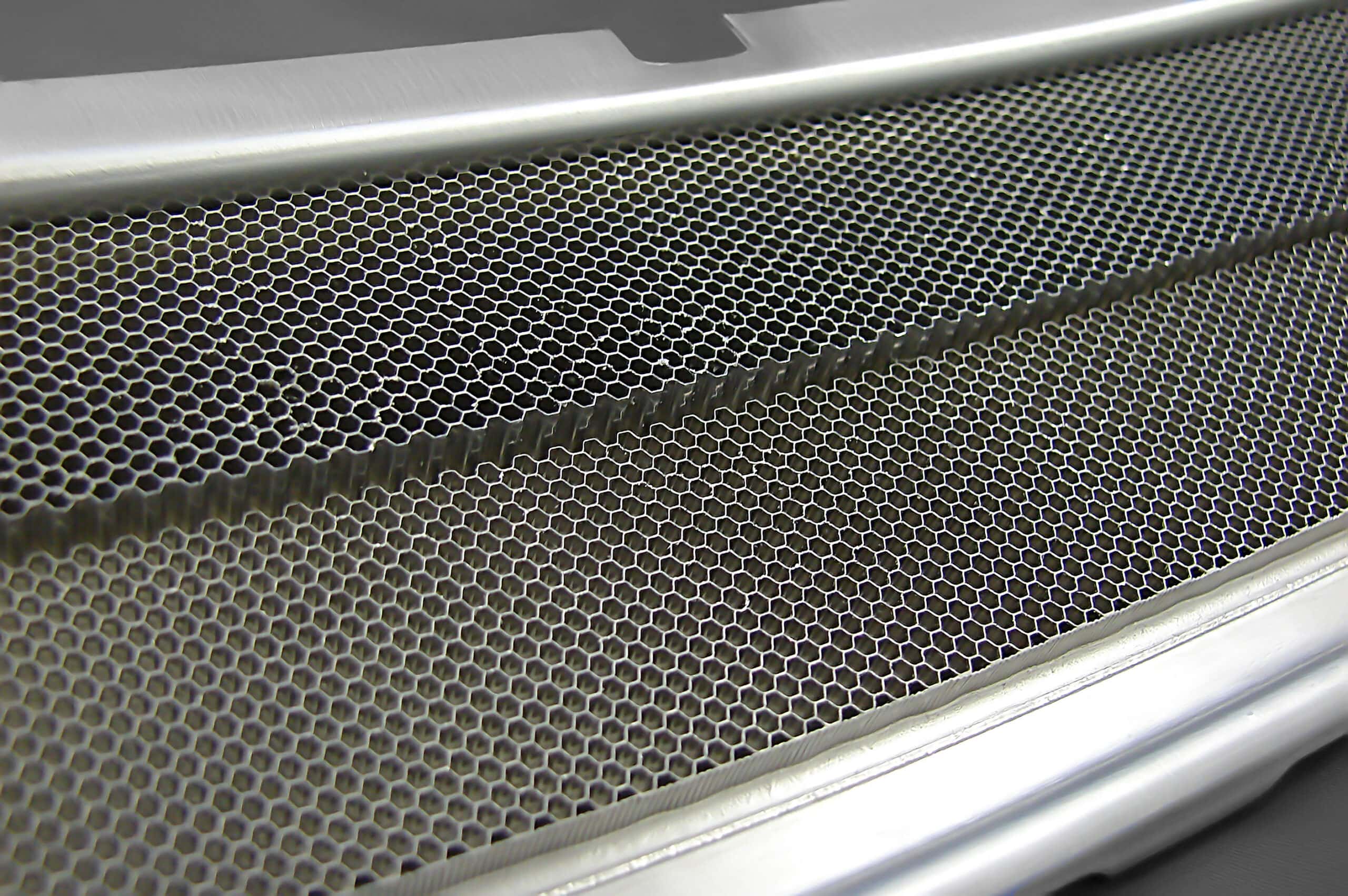

Byron Honeycomb Brazing is most commonly used in jet engine and land base turbines, either OEM or overhaul.

Byron Products is a leader in advanced manufacturing processes, specializing in the development and implementation of cutting-edge techniques to meet the needs of diverse industries. Among our many innovative solutions is honeycomb brazing, a critical process used in various sectors to create strong, lightweight structures.

What is Honeycomb Brazing?

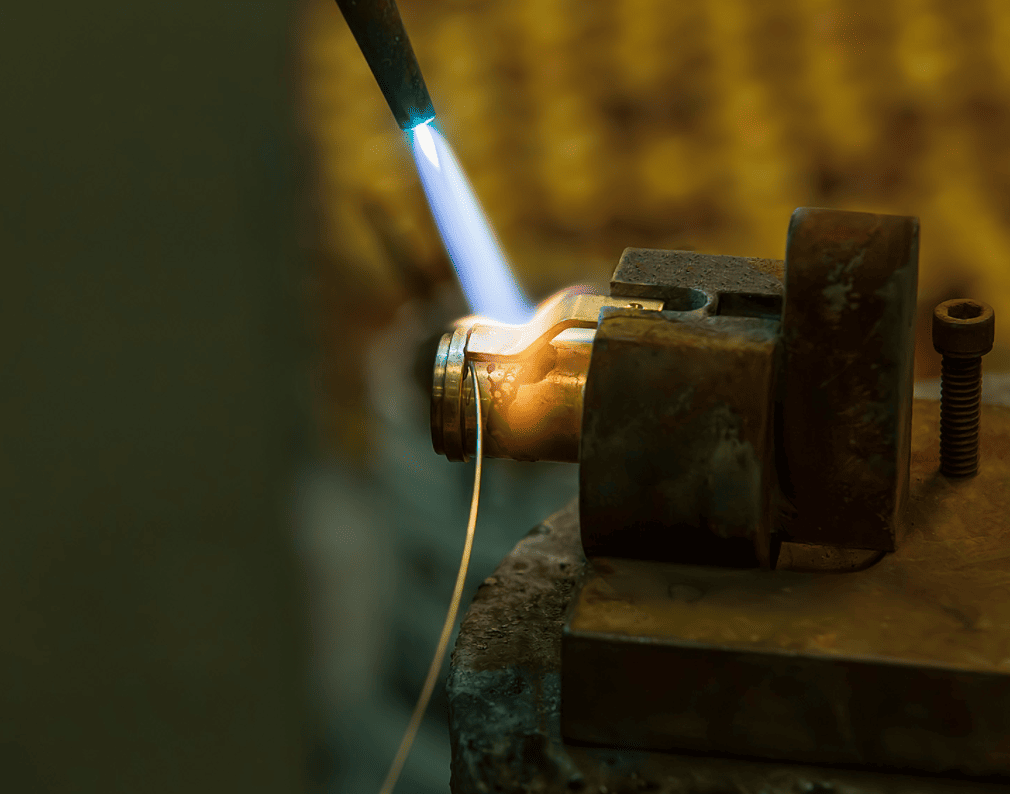

Honeycomb brazing is a joining process that involves bonding honeycomb structures to other materials using a filler metal. This technique offers numerous benefits, including enhanced structural integrity, lightweight construction, and increased durability. By filling the gaps between honeycomb cells with brazing filler metal, the resulting component achieves superior strength and stability.

Alternatively, braze tape can be used instead of powder. The honeycomb is then vacuum furnace brazed.

Honeycomb Brazing Capabilities and Industries Served

- Aerospace: Our honeycomb brazing capabilities are integral to the production of components for commercial and military aircraft, satellites, and other aerospace applications.

- Defense: With our expertise in honeycomb brazing, we provide critical components for a wide range of defense systems, including combat vehicles, missiles, and radar equipment.

- Automotive: Honeycomb structures are increasingly being used in the automotive industry for their lightweight and strength properties.

- Medical: Our innovative honeycomb brazing techniques play a vital role in producing medical devices and instruments that require both strength and precision.

- OEM + Aftermarket: Our honeycomb brazing services cater to the needs of original equipment manufacturers (OEMs) and aftermarket suppliers in various industries.

- Power Generation: Honeycomb brazing is essential in manufacturing components for power generation equipment, including gas turbines and heat exchangers.

- Commercial Applications: We also provide honeycomb brazing services for various commercial applications, such as electronics, telecommunications, and industrial equipment.

- Wind Power: Honeycomb brazing is crucial in the production of wind turbine components, such as blades and gearboxes, to withstand harsh environmental conditions.

Advantages of Byron Products' Honeycomb Brazing

- Superior Quality and Precision: Our advanced techniques and strict quality control ensure exceptional component performance.

- Cost-Effectiveness: Efficient processes and expert craftsmanship provide high-quality solutions at competitive prices.

- Customization Options: We offer customized solutions to meet specific client needs and application requirements.

- Expertise and Innovation: With over 40 years of industry experience, we optimize processes to excel in challenging market conditions

Applications of Byron Products' Honeycomb Brazing

- Honeycomb Vanes: Used in aerospace and gas turbine engines, our honeycomb vanes provide lightweight durability and increased efficiency.

- Honeycomb Seals: Our precision brazing techniques create strong and durable honeycomb seals for various industrial applications.

- Honeycomb Rings: With our advanced brazing technology, we produce honeycomb rings that are essential components in jet engines and other high-performance applications.

- Honeycomb Shrouds: Our brazing capabilities allow us to create honeycomb shrouds that provide superior thermal protection in gas turbine engines.

Why Choose Byron Products for Honeycomb Brazing?

Choosing Byron Products for your honeycomb brazing and honeycomb welding needs ensures you benefit from our extensive expertise and experience. We are committed to innovation and excellence, continuously investing in research and development to improve our processes and deliver superior products through honeycomb seals, honeycomb vanes, honeycomb rings, honeycomb shrouds, and much more.

Honeycomb Brazing with Byron Products

Experience the superior quality and precision of Byron Products’ honeycomb brazing and honeycomb welding solutions. Our team is committed to providing personalized service and innovative solutions to meet the demands of your industry. Get in touch with us today to discuss your specific honeycomb seal needs.