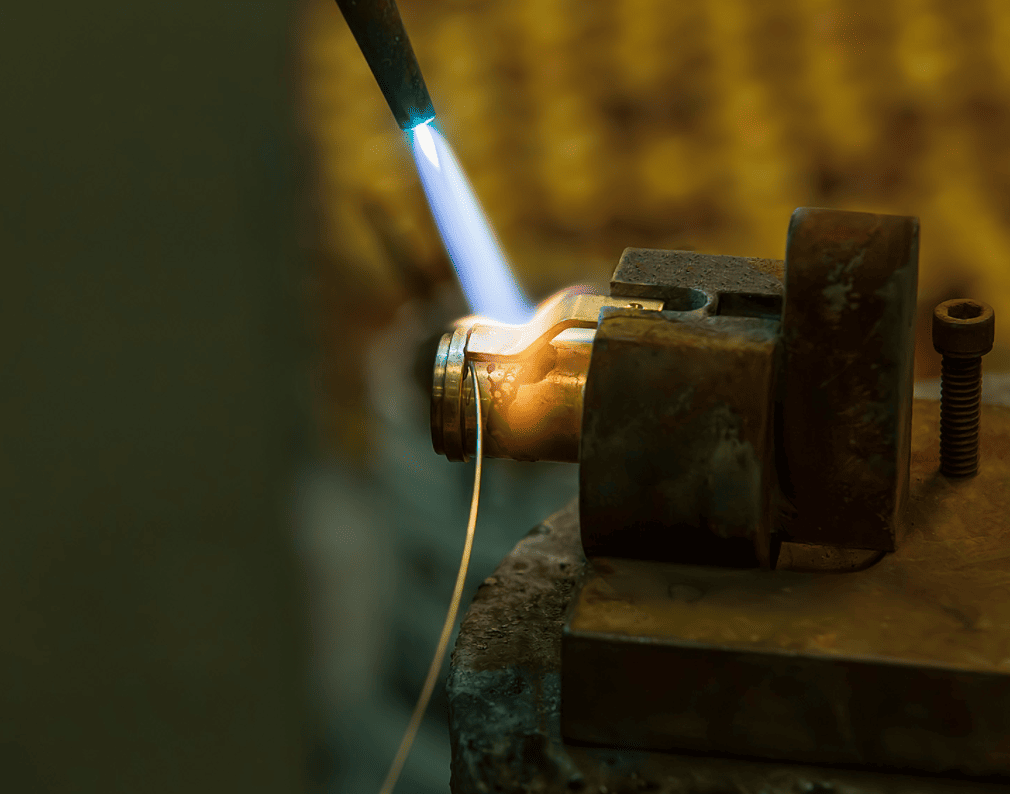

Torch Brazing

At Byron Products, torch brazing is a key thermal joining method for high-precision assemblies across a range of industries. This process is especially effective for small-batch production, prototype work, and components that require close operator control and accuracy.

Torch brazing involves heating a joint area using an open flame, usually generated by oxy-fuel or air-fuel torches, and then introducing a filler metal to form a strong, sealed bond. The technique is ideal for parts that cannot be exposed to high-temperature environments or that feature irregular geometries where consistent heat application is required.

Process / Capabilities

- Silver Brazing

- Induction parameters are highly repeatable

- Stainless Steel Hardening

Industries Served

- Aerospace

- Power Generation

- Automotive

- Defense

- Commercial Applications

Advantages

- Small Batch

- Precision

Certifications

- ISO 9001

- AS9100

- Honeywell Approved

- Emerson Approved

Technical Capabilities

Our torch brazing service is built around careful process control and skilled operator execution. Each brazed part is processed individually, allowing for close monitoring and precision.

Highlights of our torch brazing capabilities:

- Manual and semi-automated brazing stations

- Controlled heating for low thermal distortion

- Broad compatibility with stainless steels, carbon steels, copper alloys, and more

- Use of flux or fluxless processes based on customer requirements

- Ideal for small production runs, prototypes, and assemblies with complex shapes

Use of Induction Torch and Complementary Methods

In certain situations, induction torch systems may be incorporated to support consistent heating. While torch brazing provides direct flame application, induction heating relies on electromagnetic fields to heat the workpiece.

Comparison of torch brazing and induction heating:

- Torch brazing excels with:

- Complex or irregular geometries

- Hard-to-reach joints

- Assemblies requiring operator control

- Brazing with induction offers:

- Faster cycle times

- Precision heating in defined areas

- High repeatability for consistent output

Byron Products offers both torch brazing and induction brazing services, allowing us to apply the most efficient method based on the part design, production volume, and material type.

Process Control and Operator Training

Brazing quality depends heavily on technician skill and adherence to process guidelines. All Byron brazing technicians are trained in internal procedures as well as customer-specific standards. Certification is maintained through ongoing evaluation and documentation.

Process advantages include:

- Consistent joint strength and visual finish

- Controlled atmosphere options to reduce oxidation

- Custom fixtures to support accurate part alignment

- Use of temperature indicators and thermal sensors for repeatability

Industry Standards and Certifications

Byron Products operates under defined quality protocols that align with the strict requirements of aerospace, power generation, and other high-spec industries. We hold ISO 9001 and AS9100 certifications, reflecting our commitment to controlled, repeatable processes.

We are also an approved supplier for major OEMs, including Honeywell and Emerson, demonstrating consistent performance and adherence to customer-specific standards. All brazing operations are fully traceable, with documentation structured to meet NADCAP-level expectations—even for clients who do not require full NADCAP certification. This approach guarantees a high level of confidence in both the brazed joints and the supporting quality records.

Why Choose Byron Products

With decades of induction brazing services experience, Byron Products brings deep technical knowledge and manufacturing flexibility to every project. We support customers from initial process planning through final part inspection.

Advantages of working with Byron:

- Broad material expertise

- Proven brazing methods for complex assemblies

- Engineering support for joint design and fixture development

- Fast response for prototypes or urgent repair work

- Ability to shift between torch and induction methods based on the application

Contact Byron Products

To discuss your project, request a quote, or get technical input on your brazing needs, contact Byron Products today. Our team is ready to support your production goals with proven brazing solutions.