Vacuum Heat Treating

Byron Products is a leading authority in the realm of vacuum heat treating, providing advanced heat treating services backed by NADCAP certification. Our capabilities cover a variety of furnace sizes, facilitating both small-batch and high-volume production. We develop processes with our customers annealing to age hardening, always with a focus on meeting time constraints and delivering products of superior quality.

Process and Capabilities

Byron Products stands out in the industry with its wide-ranging process capabilities. Our heat treating proficiencies include

- Solution heat treating

- Precipitation hardening

- Age hardening

- Annealing

- Normalizing

- Full process development

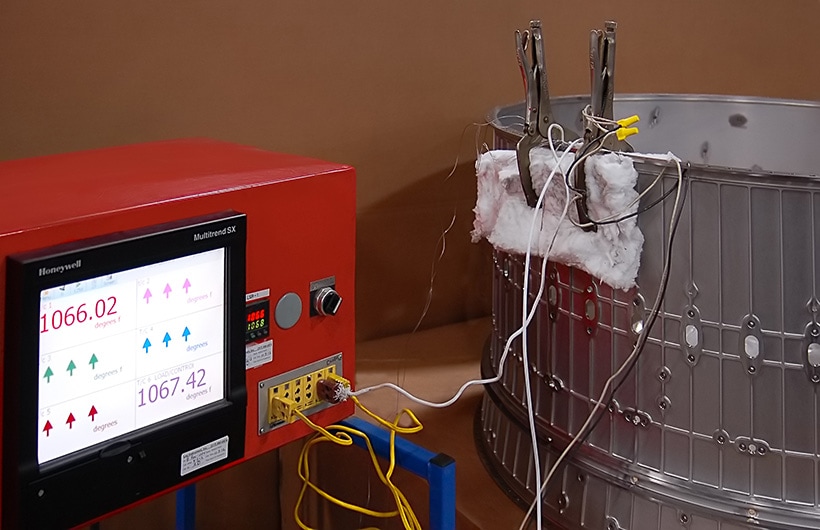

Variables such as temperature, temperature ramp rate, cool rate, hold time, and atmospheric condition all play a major role in the heat treatment process. Parts are quenched in the vacuum chamber after brazing and heat treating with Argon and/or Nitrogen.

Our process capabilities extend across a variety of materials. We handle stainless steel with the same ease as nickel and nickel-based alloys, titanium alloys, cobalt-based alloys, and copper alloys. Each material comes with its unique properties and processing needs, and our team has the experience and training to handle them all.

Industries Served

Our vacuum heat treating services are applicable across a broad spectrum of industries. The aerospace industry benefits from our services for their aircraft components. Similarly, our heat treatment processes are integral to power generation companies, contributing to more efficient and durable machinery.

In the medical field, our services play a significant role in the longevity and performance of medical devices, while the automotive and defense sectors rely on us for superior component performance. Our heat treating services cater to a range of commercial applications, strengthening equipment for businesses across various industries.

Advantages

Choosing Byron Products for your vacuum heat treating needs brings a host of advantages. We vacuum heat treat customer components every day and have just as much experience in heat treating as we do brazing. We can also manage large batch runs and small batch runs with equal efficiency, always ensuring repeatable, accurate results. Our processes reduce distortion and waste, contributing to overall operational efficiency.

The treated parts retain their brightness, enhancing their aesthetic appeal. We pride ourselves on quick turnaround times and tightly controlled processes, ensuring your timelines are met. Our operators are not only trained but also certified, ensuring your products are in capable hands. We use state-of-the-art equipment to guarantee precision and reliability.

Certifications

Our commitment to quality and precision is reflected in our numerous certifications. We are NADCAP approved, indicating our adherence to the highest standards in the aerospace and defense industries. Our ISO 9001 and AS9100 certifications underline our commitment to quality management and customer satisfaction.

We are also GE Approved, Rolls-Royce Approved, Emerson Approved, and hold a FAA Repair Station (FAA#YB5R630Y) certificate.

Byron Products is your one-stop destination for vacuum heat treating services. With a versatile range of process capabilities, industry applications, and an array of advantages, we stand poised to deliver top-tier solutions tailored to your needs. Our multiple certifications bear witness to our commitment to quality and customer satisfaction, further solidifying our position as a leader in the vacuum heat treating sector.

Process / Capabilities

- Solution Heat Treating

- Precipitation Hardening

- Age Hardening

- Bright Annealing

- Stainless Steel

- Nickel & Nickel Base Alloys

- Titanium Alloys

- Cobalt Base Alloys

- Copper Alloys

Advantages

- Large Batch Runs

- Small Batch Runs

- Repeatable Accurate Results

- Reduced Distortion & Less Waste

- Bright Parts

- Quick Turn Around

- Tightly Controlled Process

- Trained/Certified Operators

- State of the Art Equipment

Industries Served

- Aerospace

- Power Generation

- Medical

- Automotive

- Defense

- Commercial Applications

Certifications

- NADCAP approved

- ISO 9001/AS9100 D

- GE Approved

- Rolls-Royce Approved

- Emerson Approved

- Honeywell Approved

- Siemens Approved

- FAA Repair Station -FAA#YB5R630Y