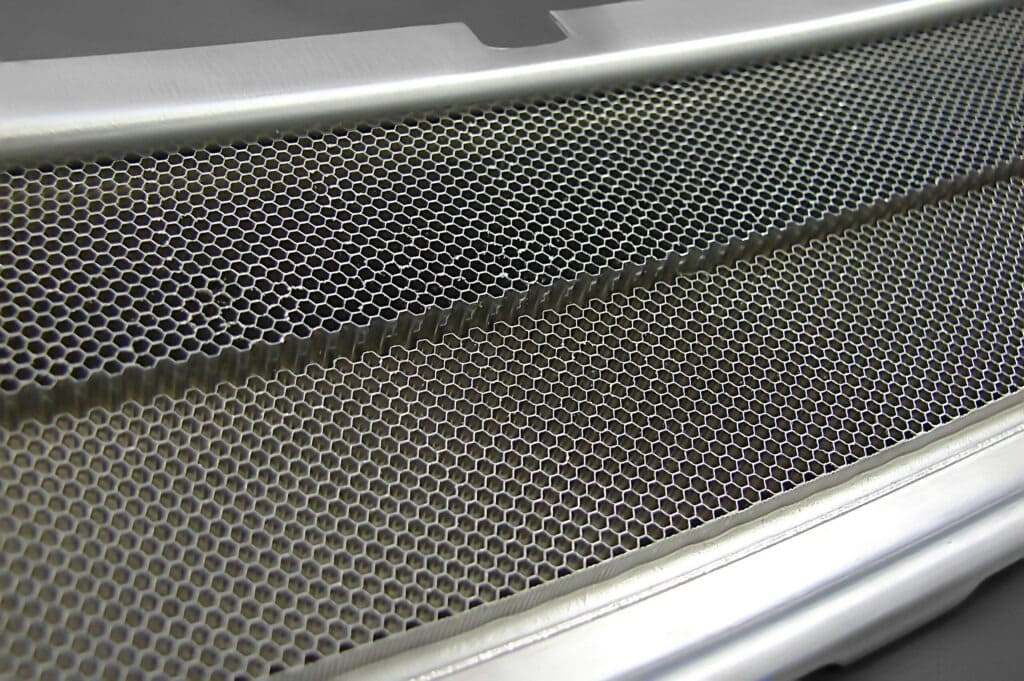

At Byron Products, we can take care of a wide variety of thermal processing needs – and honeycomb brazing is one of them. For those who don’t know, honeycomb brazing is used most commonly in the aerospace industry, and we’re proud to say we specialize in this complex thermal procedure.

The process of honeycomb brazing is intricate and sophisticated. Most typically, this process is applied when creating gas seals in aviation. These seals are usually used inside jet engines like the ones that provide propulsion for passenger jets. Similarly, a gas seal can be used to generate power inside a gas turbine.

The Honeycomb Brazing Process Explained

The reason behind Honeycomb seals being required in turbines surrounds temperature concern. Because engine parts tend to get larger as temperature increases, honeycomb brazing is used to preserve the viability of not only the blades, but also the turbine wall. It’s also important to remember: ensuring the appropriate wear characteristics at the blade/honeycomb interface throughout the process is integral to facilitating smooth operation.

At Byron Products, our engineers take a very tactful approach to honeycomb brazing. We purchase meticulously machined honeycomb from highly-trusted business partners we have worked with for decades now. We then usually resistance-weld the honeycomb to a backing plate with a precise, press-fit. An alloy is introduced in powder form and we use a type of hair spray (yes, hair spray) to get the powder to set. There are also other methods, like using a braze tape instead of powder. The honeycomb is vacuum furnace brazed.

What Other Industries Use Honeycomb Brazing?

The honeycomb structure is so popular due to its practical design – which boasts high strength and low weight. It entails joining the honeycomb surface to a base structure or backing ring to be used as a gas seal.

Due to its efficient design, it’s no wonder the process is used for a variety of different reasons. In fact, honeycomb brazing use cases don’t just stop and end with aviation. They are also especially useful for a variety of applications on other items such as train doors, aircraft bulkheads, floors, and ceilings. Honeycomb brazing is also specifically useful in power generation – specifically wind power.

Honeycomb Brazing at Byron Products – Why Choose Us?

At Byron Products honeycomb brazing is one of our core practices. Either for OEM or overhaul, the honeycomb we braze is most commonly used in jet engines and land base turbines. Our engineering staff is very familiar with these processes and specifications in any industry and are available to discuss needs unique to your business. Not only that, we’re pleased to say we’ve earned the following certifications for our honeycomb brazing:

- NADCAP approved

- ISO 9001

- AS9100

- GE Approved

- Rolls-Royce Approved

- Emerson Approved

Our highly-skilled team of engineers specialize in honeycomb seals, honeycomb for structural assemblies, and resistant tacking; we’d love to talk to you today about how we can best support your honeycomb brazing requirements.