Localized Stress Relief (LSR)

For some of the most precise needs within metal components, including in aerospace and related industries, a common process used is known as Localized Stress Relief, or LSR. LSR has a number of sub-processes, from local stress relief heat transfer to local stress relief weld repair and more, and properly applying these processes can have enormous value across several key industries.

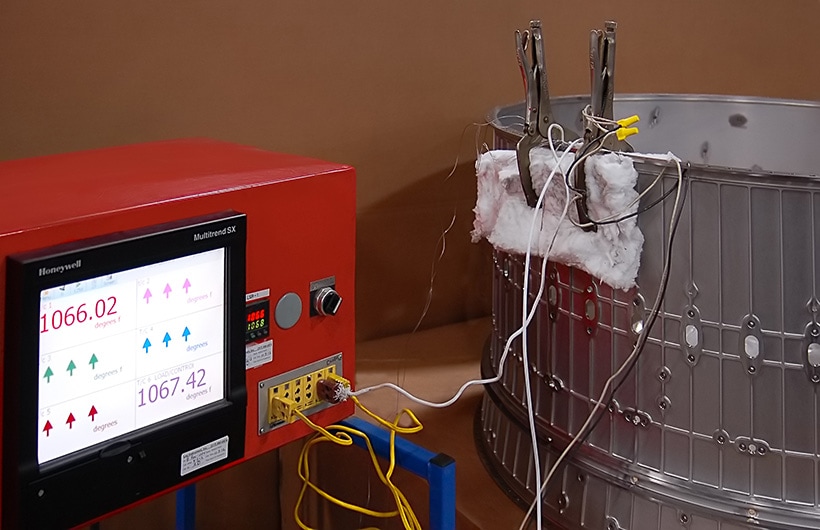

Byron Products offers high quality heat treatment services, which includes our Localized Stress Relief (LSR) process. LSR refers to the normalizing process on a targeted area (such as a weld seam) in a controlled environment which does not affect the tolerance of the surrounding base metal. LSR is mostly utilized in the overhaul and repair of aerospace engine and land-based turbine components.

An Effective Local Heat Treatment

Localized Stress Relief is a local heat treatment which, as the name implies, involves the application of heat to anneal stresses in a targeted area. It’s performed by heating the affected area to a specific temperature using cartridge or ceramic heaters. An argon heat gun can also be used in certain scenarios for more precise results.

Following the prescribed temperature hold cycle, the area is cooled to spec. The result is a more stable microstructure on the affected area, reducing the risk of failure on the repair site.

Benefits of Localized Stress Relief and Stress Relieved Steel:

- Minimizes, reduces, or eliminates residual stresses present after welding

- Prevents premature failure of a part

- Lowers risk of post-op dimensional changes

- Avoids need to heat treat entire part

Applications of Localized Stress Relief

- Aerospace engine components

- Land-based turbines

- Pressure vessels

- Multiple-material assemblies

- Machining defect and Weld repair

Both large and small assemblies are benefited by stress relief heat treatment processes that require weld repair following machine defects. Local heat treatment is a crucial process in any industry with overhaul and repair needs, and Byron Products is a spearheader in LSR solutions and heat treating service.

Local Stress Relieving at Byron Products

As a certified FAA Repair Station -FAA#YB5R630Y, Byron Products is the key to a cost-efficient overhaul/ repair solution. With our cutting-edge technology and highly-trained personnel, Byron Products is a proven value-add partner for this reliable local heat treatment process.

We offer several specific LSR solutions, including local stress relief heat transfer and local stress relief weld repair, to ensure the optimal performance and lifespan of critical components. Our LSR process can reduce residual stresses and mitigate distortion, improving part integrity and reducing the risk of failure.

Contact us today to learn more about our services or to get started. Our team is ready to answer any of your questions and we can provide a quick quote of our various reliable solutions for all your heat treatment needs!

Process / Capabilities

- Weld Repair Stress Relief

- Controlled Ramp and Soak Times

- Heat Under Argon Atmosphere

- Heat Inside Insulated Environment

- Produce Detailed Furnace Charts

Advantages

- Quick Turn Around

- Tightly Controlled Process

- Trained/Certified Operators

- Prevent Altering Final Machine Tolerance

Industries Served

- Aerospace

- Power Generation

- Defense

- Commercial Applications

Secondary Operations

- Assembly

- Cleaning

- Machining

- Grinding

- Blasting

- Non Destructive Testing

Certifications

- NADCAP approved

- ISO 9001/AS9100 D

- GE Approved (S-559)

- Rolls-Royce Approved

- Honeywell Approved

- Siemens Approved