Certified Heat Treating

For over 35 years, Byron Products has been at the forefront of heat treating companies. We have the experience, capability, and dedication to provide solutions tailored to meet your specific needs, regardless of the complexity of your project.

Our specialty lies in heat treating services, particularly certified steel treating and high-temperature aerospace heat treating. Our vacuum and atmosphere furnaces, state-of-the-art in design and meticulously maintained according to AMS 2750 standards, allow us to perform diverse thermal processes on a wide array of materials, including steel, stainless steel, Inconel, Titanium, and other specialty metals.

Vacuum Heat Treating: Meeting Your High-Quality Standards

We’re not just any heat treat company. Byron Products is committed to providing advanced NADCAP-certified vacuum heat treating services that cater to your unique needs, whether they range from small batch production to high volume requirements. Our team, known for its agility in addressing your stringent vacuum heat treating timelines, is dedicated to delivering a top-tier product every time.

Atmosphere Heat Treating: Precision in Every Process

At Byron Products, we provide Atmosphere Heat Treating, employing continuous belt furnaces, batch ovens, and retort furnaces. Our furnace atmospheres encompass gases, all maintained, calibrated, and surveyed in accordance with AMS 2750. Rest assured, our seasoned atmosphere heat treat operators carry out each process with meticulous attention to detail, ensuring that we meet your specific requirements precisely.

Tempering: Mastering the Art of Resilience

We recognize the significance of tempering in heat treating processes. With our ability to temper in vacuum, atmosphere, or air furnaces, we can ensure the reliability and performance of your components. All our operations are continuously monitored and conducted under the stringent standards of our industry to deliver quality parts efficiently.

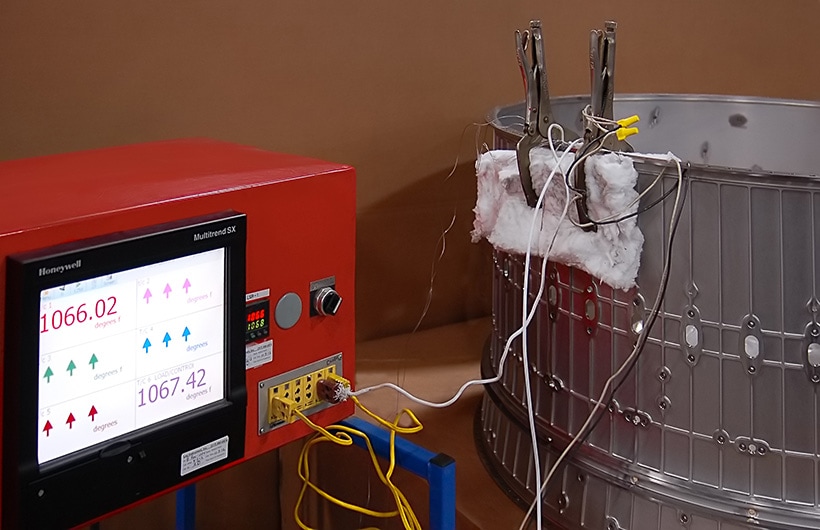

Localized Stress Relieve: The Art of Precision

Our Localized Stress Relieve (LSR) process applies targeted heat to a weld repair area on a final part or assembly, preserving other areas from affecting tolerances. Whether we’re using cartridges or ceramic heaters, or an argon heat gun, we can perform this heating process in a protective atmosphere as required.

Custom Solutions: We’re More Than Our Main Capabilities

While we’ve outlined our key services above, we embrace a “sky’s the limit” philosophy at Byron Products. We take pride in our ability to develop unique, custom heat treat solutions to meet your diverse needs. From the aerospace industry to the medical industry, we are more than capable of handling custom orders beyond our primary capabilities.

At Byron Products, we see heat treating as more than just a process; we view it as a partnership to help you achieve your goals. We understand that every project is different and requires a unique blend of heat treating solutions. With our team’s expertise and our state-of-the-art facilities, we’re ready to take on any heat treating challenge.