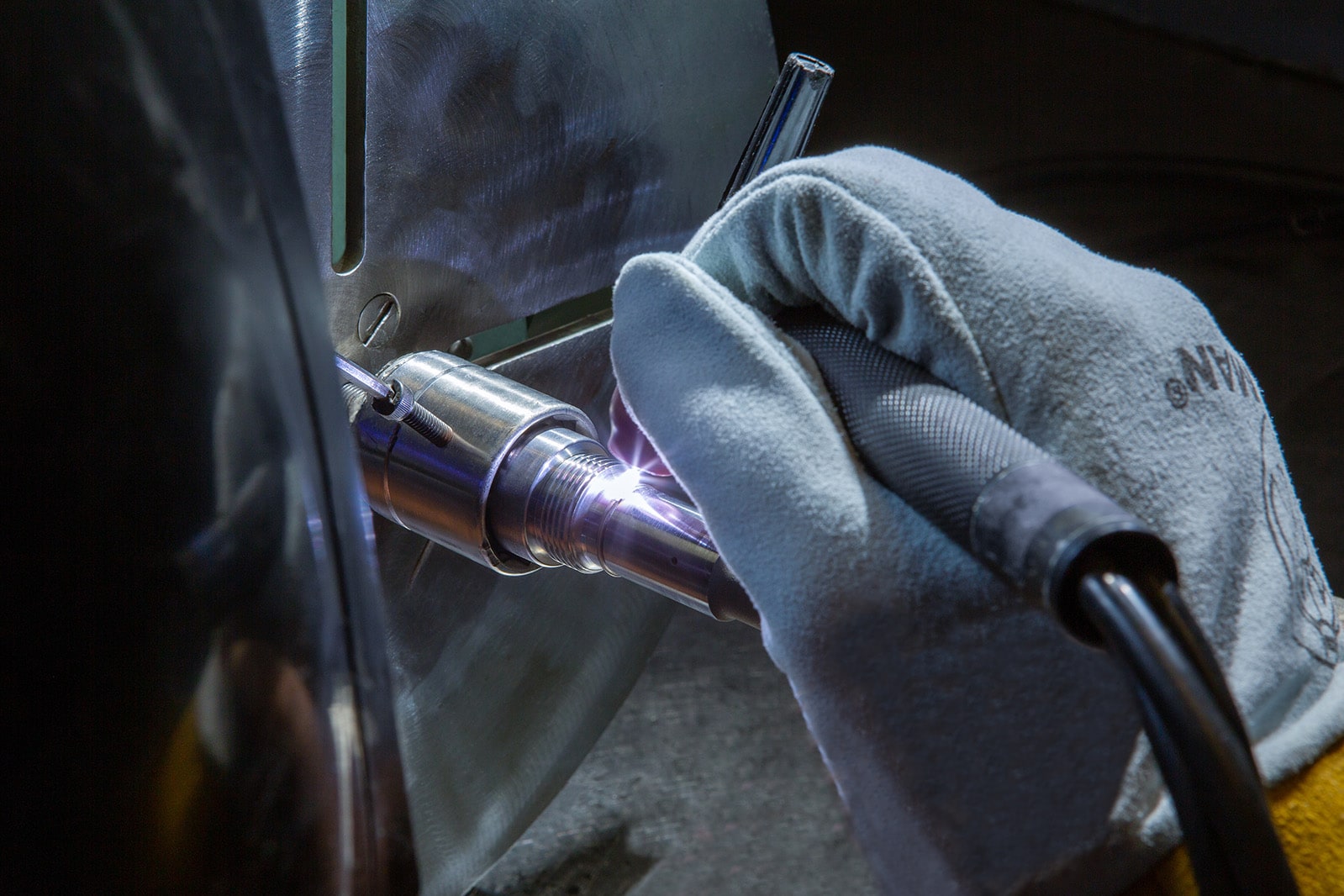

GTAW/TIG Welding

Byron Products specializes in TIG welding services. Our 3 vacuum atmosphere chambers are capable of welding the most difficult oxidizing materials. Our welders are certified in accordance with AWS D17.1, and we are capable of certifying our operators to other standards as required.

Process / Capabilities

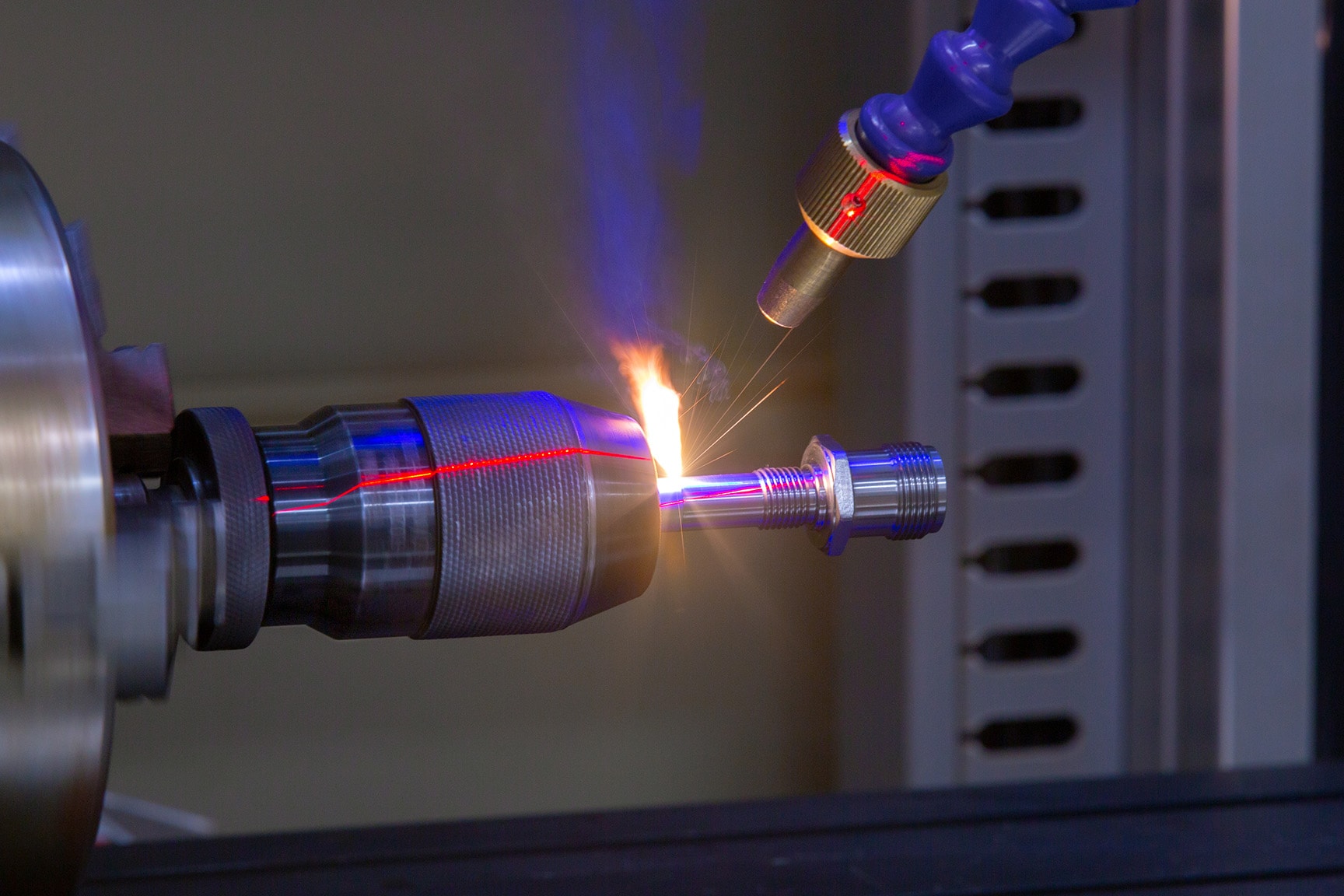

- Vacuum Chamber Welding

- Thin Gage Welding

- Delicate Assembly to Large Structure

- Fixture Welding

- Stainless Steel

- Carbon & Alloy Steels

- Nickel & Nickel Base Alloys

- Aluminum Alloys

- Titanium Alloys

- Cobalt Base Alloys

- Copper Alloys

- Refractory Alloys

- Reactive Alloys

- Magnet Alloys

- Certification & Inspection

Industries Served

- Aerospace

- Power Generation

- Medical

- Automotive

- Defense

- Commercial Applications

Certifications

- Nadcap accredited

- ISO 9001

- AS9100

- GE Approved

- FAA Repair Station -FAA#YB5R630Y

- Rolls-Royce Approved

- Emerson Approved

Why Choose Byron Products for TIG Welding?

Byron Products stands out as a leading provider of TIG welding services because of our skilled welders, advanced equipment, and unwavering commitment to quality. With the ability to handle a wide range of materials and industries, we are the trusted partner for welding projects of all sizes and complexities.

Whether you need welding for a small component or a large structure, our TIG welding services will deliver the precision and reliability your project requires. Contact Byron Products today to learn more about how our GTAW and TIG welding services can support your needs.