Atmosphere Heat Treating: Hydrogen, Argon, Nitrogen Processes

Byron Products is at the forefront of advancing metal’s mechanical properties through our expert atmosphere heat treat services. We leverage our expert atmospheric heat treating services to deliver quality products and enhance the performance of your components.

Our Heat Treating Services

At Byron Products, our advanced facility is outfitted with specialized furnaces to meet diverse metal heat treating service needs:

- Continuous Belt Furnaces: Ideal for high-volume production, these furnaces provide uniform heat treatment quickly and efficiently, suitable for tempering and hardening.

- Batch Ovens: These ovens allow for adjustable batch sizes and precise temperature control, perfect for specialty applications involving different materials or complex shapes.

- Retort Furnaces: Offering superior atmosphere control, these are essential for treating reactive metals and preventing contamination.

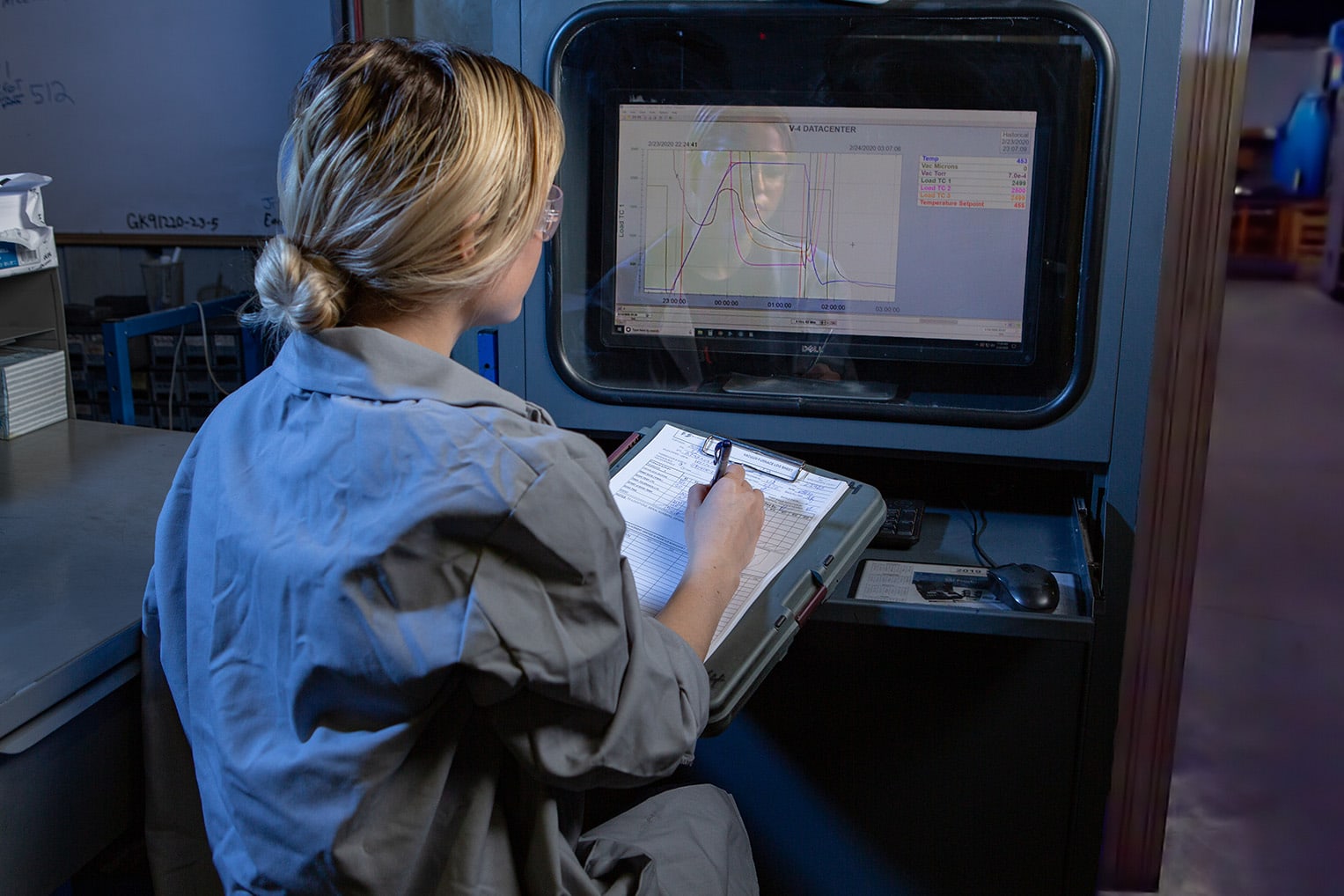

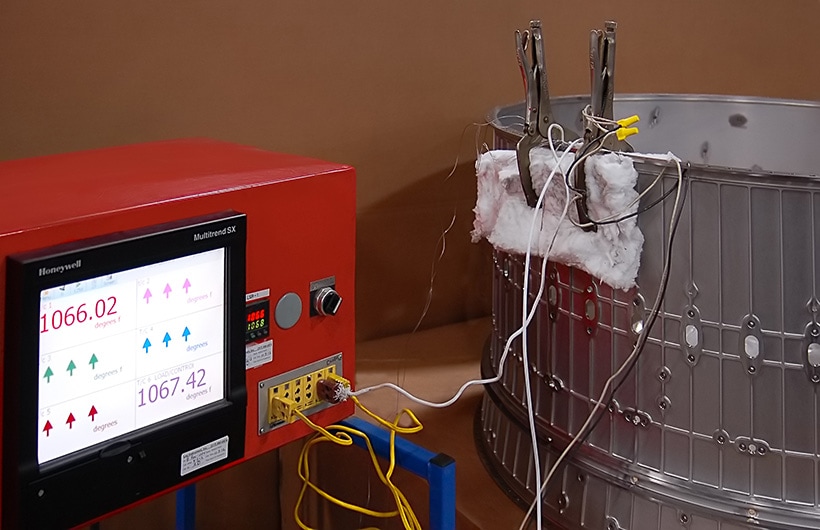

Each piece of equipment is meticulously maintained and calibrated to AMS 2750 standards, ensuring precision in every process. Our expert operators tailor treatments to meet your specific requirements, ensuring consistency and quality in every batch.

Process / Capabilities

Hydrogen

Hydrogen is utilized in our industrial heat treating processes primarily to reduce atmospheric oxygen, preventing oxidation and ensuring a cleaner finish. This gas facilitates the achievement of desired mechanical properties like hardness and ductility through more uniform treatment across different metals.

Argon

Argon is employed in our furnaces to create an inert atmosphere, essential for treating metals sensitive to nitrogen and hydrogen. This capability is particularly beneficial for special alloys used in high-tech industries, which require precise and non-reactive conditions to maintain their unique properties during the heat-treating process.

Nitrogen

Nitrogen is chosen for its ability to stabilize the furnace atmosphere at high temperatures. It is particularly effective in hardening and annealing processes, where its use results in stronger, more resilient metal components. Our capability to manipulate the nitrogen atmosphere is crucial for industries requiring material reliability and performance.

Advantages of Choosing Byron Products

Selecting Byron Products for your heat treating service needs means benefiting from our continuous large volume capabilities, which translate to cost savings for you. Our process consistency and state-of-the-art equipment, operated by trained and certified staff, ensure a tightly controlled process that upholds the highest quality standards.

Industries Served

Byron Products proudly caters to diverse industrial heat treating sectors, showcasing our capacity to adapt to the unique challenges and demands of different industries:

- Aerospace

- Power Generation

- Medical

- Automotive

- Defense

- Commercial Applications

Certifications

Our certifications reflect our dedicated pursuit of excellence and adherence to the stringent requirements of industry-leading oversight bodies. They include:

- NADCAP approved

- ISO 9001

- AS9100

- GE Approved

- FAA Repair Station – FAA#YB5R630Y

- Rolls-Royce Approved

- Emerson Approved